Accidents at work not only entail financial and logistical costs, but – most importantly – can lead to a threat to the health and life of employees. Although many companies invest in personal protective equipment, health and safety training and space marking, they often lack the tools to monitor behaviour and reactions in real time.

This is where artificial intelligence (AI) based video analysis comes in handy – technology that can not only record but also understand and respond to hazardous situations before an accident even occurs.

Data: what do the statistics say?

In 2022, there were approximately 2.97 million occupational accidents in the European Union resulting in at least 4 days of incapacity for work and 3,286 fatal accidents. The main causes were falls, machinery-related injuries, collisions and musculoskeletal strains – particularly common in industries such as manufacturing, construction and logistics1.

The average costs of treatment, rehabilitation and compensation vary depending on the type and severity of the injury or illness, the country and the healthcare and social security system. For example, in the UK, the average cost of a work-related injury in 2018/19 was £8,5002. However, these are only the direct costs and do not take into account lost productivity or the impact on the company’s reputation.

Monitoring compliance with safety rules using image analysis is a technology that can be used as a strategic tool to help companies protect their employees while reducing financial losses.

What is AI video analysis?

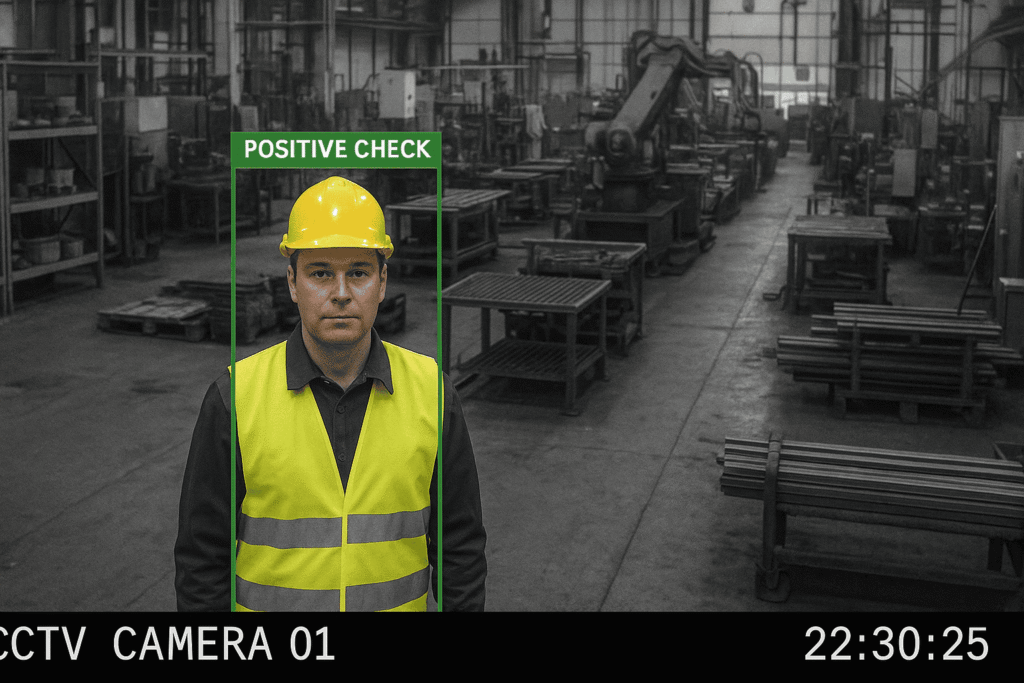

AI video analytics is a system that combines industrial cameras with software that analyses images in real time. Artificial intelligence can:

- recognize objects (e.g. people, vehicles, machines),

- detect behaviour (e.g. falls, collisions, dangerous movements),

- identify violations of safety rules (e.g. no helmet, entering a dangerous zone),

- automatically notify the appropriate people or trigger an alarm.

How does video analysis help reduce accidents?

1. Real-time detection of dangerous behaviours

The AI image analysis system can detect:

- entering a prohibited zone,

- speed violation of a vehicle (e.g. a forklift) or crossing designated communication lines,

- collision or other accidents,

- lack of an employee at a position (e.g. a machine operator),

- long-term immobilization of an employee (fainting signal).

This allows for immediate reaction before the incident develops into a serious accident.

2. Automatic control of the use of personal protective equipment (PPE)

The vision system can detect:

- lack of a helmet,

- lack of a warning vest,

- lack of protective glasses or gloves.

Companies can thus automate the enforcement of health and safety regulations – without the need for manual control.

3. Identifying threat patterns

The collected data allows you to analyse where and when dangerous situations most often occur:

- which zone is most frequently violated,

- which shifts or teams are more exposed,

- which types of activities lead to the most frequent incidents.

This is the basis for better training, changes to the hall layout or strengthening of signage.

Examples of applications in various industries

AI video analysis is used in many work environments – from heavy industry to logistics. Below we describe how specific sectors use this technology to improve safety:

Industry and production

In production plants, AI supports the control of the use of personal protective equipment, such as helmets, warning vests and gloves. The system can automatically detect the lack of equipment in an employee entering a dangerous zone. In one European automotive plant, the implementation of such a system reduced the number of incidents related to PPE by over 20% within six months.

Warehouses and logistics

In warehouses, AI tracks the movement of forklifts and pedestrians, detecting collisions, blocking traffic routes or moving in prohibited directions. One logistics operator, after implementing such a solution, almost completely eliminated internal collisions during rush hours.

Construction

On construction sites, video analysis allows detecting unauthorized access to dangerous zones, moving without protection at heights or potential falls. AI can also identify the lack of a harness or moving without supervision. In one infrastructure project, this system shortened the response time to incidents from several minutes to just a few dozen seconds.

Energy and heavy industry

In high-risk sectors, such as the energy or chemical industry, AI supports the control of people’s presence near live equipment, high-pressure or high-temperature areas. It can automatically generate alerts when someone is near dangerous equipment without the appropriate authorizations or protection. This significantly reduces the number of procedure violations and increases compliance with internal standards.

Is it worth it?

Definitely yes. Investing in AI video analysis is not just an expense for technology – it is primarily a saving resulting from reducing accidents, work interruptions, claims and penalties. These systems can operate on the basis of existing infrastructure (CCTV cameras, network), which significantly reduces implementation costs. Additionally, they do not require constant operator attention – they analyse the image 24/7, without fatigue and without interruptions.

For many companies, the return on investment occurs within a few months, especially in sectors with increased risk. Reduced number of accidents by 20–40%, lower insurance premiums, less downtime, better audit indicators – these are measurable effects that translate into real savings and greater safety for the entire organization.

This is an investment that not only protects people but also builds a modern safety culture and strengthens the company’s reputation as a responsible employer.

Summary

Accidents at work are not just statistics – they are a real threat to employee health, operational continuity and the company’s reputation. Traditional surveillance methods have their limitations, which is why more and more organizations are reaching for modern technologies, such as video analysis supported by artificial intelligence.

AI software enables continuous observation and interpretation of images from cameras in real time. They can recognize dangerous situations, monitor compliance with health and safety regulations and automatically notify the appropriate persons before an accident occurs. Importantly, they operate on the basis of existing infrastructure and can be implemented in stages – without the need for large outlays at the start.

Benefits? Fewer incidents, higher level of safety, lower insurance and downtime costs, better results in audits, and a greater sense of responsibility among employees. This solution combines prevention with automation – and really changes the way companies take care of their people.

In the era of Industry 4.0, video analysis is not a luxury – it is the new standard of modern and responsible occupational safety management.