Workplace Accidents – Statistical Data

In 2022, the European Union recorded 3,286 fatal workplace accidents and as many as 2.97 million non-fatal accidents resulting in at least 4 days of absence1. The dominant sectors in this regard are construction, transport, warehousing, and production. The specific nature of these industries makes them the subject to more restricted occupational health and safety regulations, and one of the key aspects is the use of personal protective equipment (PPE).

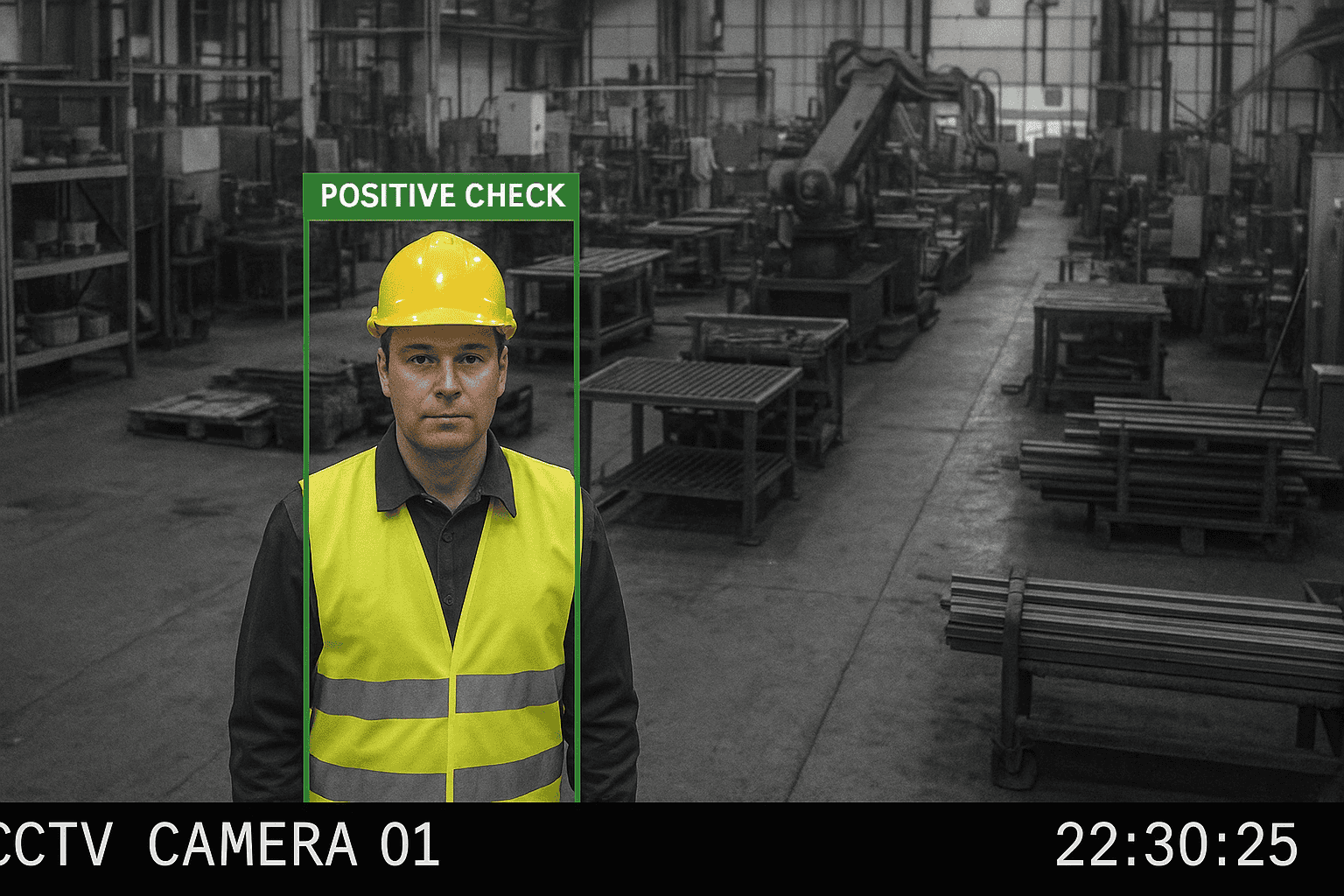

Protective measures are therefore crucial for protecting health and life, and preventing accidents can also result in measurable savings. One such solution is the automatic monitoring of personal protective equipment using computer vision, a powerful tool that can significantly improve overall workplace safety.

How Video Analytics Systems for PPE Detection Work

The rapid development of artificial intelligence (AI) has made it possible to automate many previously manual processes, including occupational health and safety monitoring and control of personal protective equipment usage.

Video analytics systems work as follows:

- Image Recording – IP cameras record images from workplaces and transmit them in real-time to an analytical server. Good image quality and stability are important to facilitate effective analysis.

- Detection and Classification – Machine learning algorithms trained on large datasets detect and recognize objects used as PPE – including helmets, reflective vests, gloves, safety glasses – as well as their proper use.

- Spatial and Contextual Analysis – The system determines whether a given employee is in an area where specific PPE is required (e.g., entry to a production hall or a machine operation zone). The associated logic helps understand whether the lack of PPE constitutes an actual safety violation.

- Instant Notifications – Upen detecting a violation, the system can send an alert to a supervisor or HSE inspector informing them about the situation. Additionally, the system will record all such situations and can generate statistics and reports for specific periods.

In summary, video analytics for PPE detection combines image recording, advanced object classification, contextual situational analysis, and instant notifications. This enables effective enforcement of occupational health and safety rules – even without the constant presence of supervisory personnel.

Solution Effectiveness

Practical examples show the real effectiveness of video analytics systems in improving workplace safety. In a large chemical production plant (producing pesticides and specialty chemicals) in India, an AI-based PPE detection system was implemented, which enabled the company to achieve a 94% compliance level with PPE requirements and reduced safety-related incidents by 67%. Importantly, this also translated into improved operational efficiency2.

This implementation shows that protective equipment monitoring systems can not only increase compliance with occupational health and safety procedures but also actually reduce the number of accidents and improve operational efficiency in a demanding production environment.

Implementation Challenges

Automation of personal protective equipment monitoring through video analytics opens new possibilities but also introduces specific technical and operational challenges.

One of the biggest problems can be environmental conditions such as dynamic lighting, dust, or fog, which can hinder PPE detection. While lighting issues can often be addressed by using appropriate cameras, in environments with high dust levels, the problem may be somewhat greater.

Another challenge can be costs and infrastructure – comprehensive AI video analytics platform implementations require appropriate computing power (GPU/CPU) and network performance, although these needs largely depend on the project scale. A huge advantage of platforms like Vidiana is their ability to integrate with existing infrastructure, which can significantly reduce investment levels. However, it should be remembered that proper camera positioning may be required for computer vision algorithms to function correctly. Additionally, much also depends on the camera parameters themselves, as image quality is one of the key aspects for performing correct analysis.

Finally, ethical and privacy aspects must be remembered – systems collect employee images, which raises concerns related to personal data protection. This does not mean that workplace monitoring cannot be used, but its implementation should have a specific purpose, employees must be properly informed in advance, and personal data must be appropriately secured.

Conclusions and Recommendations

PPE monitoring using video analytics can be an effective, scalable, and economical tool for increasing safety. It is worth choosing suppliers offering comprehensive integration, such as Vidiana, who deal not only with video analytics technology but also with implementation support, system configuration, personnel training, and post-installation service. This type of approach enables implementation of a small pilot project, which limits initial costs and allows testing the system in real conditions before scaling.

An independent study conducted by research firm Omdia, covering 140 organizations from North America and Europe, confirms that as many as 85% of respondents achieved return on investment in video analytics systems, including among others safety funtions, within 12 months. In production and logistics, this ROI often results from fewer workplace accidents, automation of supervisory processes, and increased operational efficiency3.

Implementing an automatic video analytics system for detecting personal protective equipment is an investment that pays off both in the eyes of the Labor Inspection agencies and from management’s perspective – it affects real risk reduction and increases safety awareness and culture among employees, while additionally translating into greater work efficiency.

It is worth mentioning that video analysis software also offers other functionalities that can help increase safety levels (e.g., limited access zone control) and operational efficiency (e.g., counting objects on the production line).